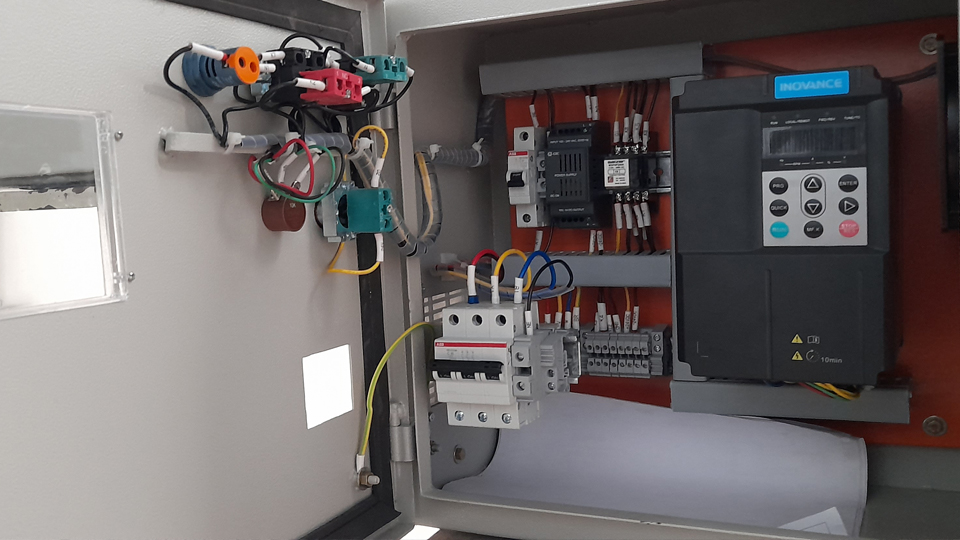

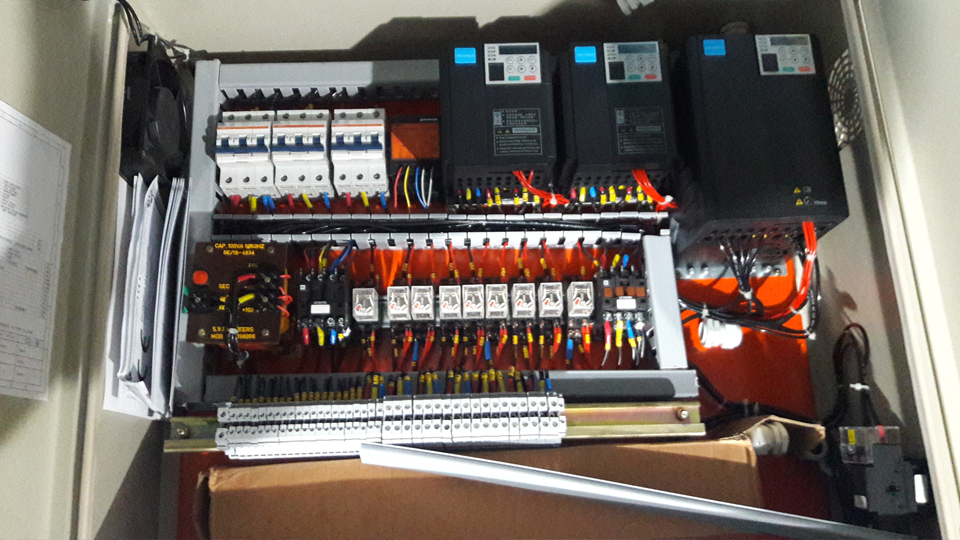

We are authorized channel partner for INOVANCE automation products.

How Servo Drives Power Industrial Automation

In the dynamic realm of industrial automation, the pivotal role played by servo drives cannot be overstated....

Reasons You Need to Invest in Industrial Automation

In today’s fast-paced manufacturing landscape, industrial automation stands as a pivotal catalyst...

Unlock Efficiency with Automation: The Power of PLC Programming

Unlock Efficiency with Automation: The Power of PLC Programming In the dynamic landscape of industrial...

Previous

Next

GENERAL PURPOSE MICRO DRIVE MD200

- 4 to 2.2kW

- Wide operating voltage : Single Phase 220VAC, 170 to 264VAC

- Internal EMC Filter

- Complies with EN61800-3 Category C2 2nd Environment

- Simplified parameter for easy start up

- Open loop V/F control; Staring torque of 150% at 3Hz; Automatic torque boost.

- Modbus or CANLinkcomms

- 2-Independent S-Ramps

- Output frequency 500Hz

- Overload : 150% for 60 Sec & 180% for 3 Sec

- In-Built Dynamic braking unit

- Side-by-Side/ Wall Mounted/ DIN Rail Mounted

GENERAL PURPOSE MICRO DRIVE MD310

- 4 to 18.5kW.

- Wide operating voltage : Three Phase 380VAC, 323 to 456VAC.

- Onboard MODBUS & optional CANlink.

- Open loop V/F & SVC control; Staring torque of 150% at 0.5Hz(SVC) and 100% at 1Hz(V/F) ; Automatic torque boost.

- Simplified parameter for easy start up

- 4-Independent S-Ramps

- Output frequency 500Hz

- Overload : 150% for 60 Sec & 180% for 3 Sec

- In-Built Dynamic braking unit

HIGH PERFORMANCE GENERAL PURPOSE DRIVE MD290

- 4 to 500kW, Three Phase 380 to 480VAC.

- Optional MODBUS-RTU, CANlink, Profibus-DP, CANopen.

- Open loop V/F; Automatic torque boost.

- 4-Independent S-Ramps

- Output frequency 500Hz

- Overload : 110% for normal duty and 150% for 60 Sec for heavy duty.

- In-Built Dynamic braking unit upto 18.5kW

- Built-in DC reactor EN61800-3 Category C2 2nd Environment.

HIGH PERFORMANCE UNIVERSAL DRIVE MD500+

- 3 Ph 380-480 Vac: 0.4 to 500 kW.

- 3 Ph 200-240 Vac: 0.4 to 90 kW.

- 1 Ph 200-240 Vac: 0.4 to 2.2 kW.

- Operation in high ambient temperatures – up to 50degC.

- Built-in DC reactor (400 V: 18.5 kW and above; 200 V: 11 kW and above.

- Conformal coated PCBs compliant to 3S2 and 3C3 environments.

- Complies to efficiency level IE2 as defined in IEC 61800-9-2.

- Control modes: V/f for induction motor, Sensorless vector control (SVC), closed loop vector control (FVC) for both induction (asynchronous) and PMS motors.

- Starting torque; 150% at 0.25 Hz for SVC; 180% at 0 Hz for FVC.

- Communication options: Modbus-RTU, PROFIBUS-DP, CANopen, CANlink, PROFINET, EtherCAT, Ethernet/IP.

- Brake control logic; inbuilt brake resistor upto 90kW.

- Application dedicated functions: Centre winder, Textile wobble control, Master slave function. 4 motor parameter sets.

- Bipolar analog input as standard (-10 to +10 V); PTC input as standard.

- Output frequency: 599 Hz.

- Encoder feedback (option): Incremental (HTL, Line Driver), Resolver, Serial encoder.

SINGLE AXIS SERVO SV660P-PULSE TYPE, SV660N-EtherCAT

- Ultra-fast 4.5 kHz current loop.

- Safe Torque Off – SIL3.

- High speed EtherCAT communications – 125 μs.

- 23 bit High resolution feedback encoder.

- Short output winding Standard, built-in, short output winding ensures safe braking if the drive is unexpectedly disabled – even in the case of a failure in the motor holding brake.

- Comprehensive data storage in case of failure.

HMI IT7000

- 3 inch, 7 inch, 10 inch and 15 inch.

- IP65 rating (front side).

- Built-in Ethernet and serial ports.

- Up to 1,024 x 768 resolution(16 M colours).

- Javascript for creation of plug-ins and dedicated communication protocols & access to external databases; Canvas control for free graphic drawing.

- Supports VNC remote access through mobile devices.

- Trend chart & oscilloscope for continuous wave sampling.

- USB & micro SD cards for easy data management; Real-time clock.

- Supports products from a wide range of 3rd party manufacturers.

- Support for OPC UA and Modbus RTU/TCP protocols.

- IIoT ready: MQTT implementation, seamlessly connects to any server.

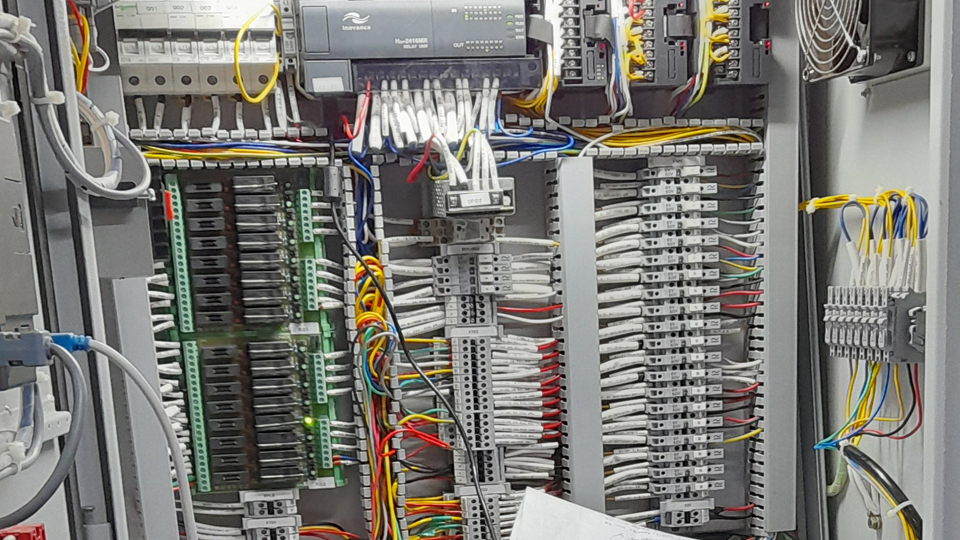

BASIC PLC H1U

- All in one CPU and power supply supporting local and remote I/O.

- 100 ns execution time per single, basic instruction.

- Program capacity: 8 K steps.

- Device memory

- Auxiliary relays 3584 points

- Timers 256 points

- Counters 256 points

- Data registers 8528 points

- High speed inputs: up to 60 kHz.

- High speed outputs: up to 100 kHz.

- Supports RS485 (Modbus-RTU) and CANlink (Inovance proprietary) communication.

- Maximum of 60 digital I/O (local), supports up to 30 remote modules (CANlink 3.0).

- Programming language conforms to IEC 61131-3.

- Ladder diagram (LD)/ Instruction list (IL)/ Sequential function chart (SFC).

HIGH PERFORMANCE PLC H3U

- All-in-one CPU, power supply and I/O.

- Basic instruction: 100ns/instruction.

- Program capacity: 64K steps.

- Device memory

- Auxiliary Relays 9216 points

- Timers 512 points

- Counters 256 points

- Data Registers 9552 points

- File Registers 32768 points

- High-speed inputs: 200kHz

- High-speed outputs: 200kHz(Standard Model) 500kHz(Motion Control Model).

- Interpolation: two-axis arc and straight line, three-axis straight line(Motion Control Model), spiral line(Motion Control Model)

- Three-axis electronic cam(Motion Control Model).

- Supports MODBUS-RTU & MODBUS-TCP & CANlink/CANopen modes.

- Maximum of 192 digital I/O(local).

- Programming language: Ladder, Instruction list, SFC